A new law to improve new trucks so their drivers can better see cyclists and pedestrians has finally come into force in Europe. The rules will substantially reduce safety blindspots – the zones in front and beside the cab that no driver, however conscientious, is able to see directly. Troublingly, however, trucks with large blind zones can still lawfully be sold until the end of 2028. There’s much left to do to truly get rid of all blindspots in new trucks.

Looking longer term, it’s clear that blindspot removal and truck electrification work well together. The wave of electrification increasingly taking hold in trucking will help finish the job. Europe’s vehicle safety law will be reviewed again after the June 2024 elections. As election campaigning gathers pace, safety advocates should push the next European Parliament to reap the benefits of new electric truck designs by getting rid of all blindspots in new trucks for good.

The blindspot problem

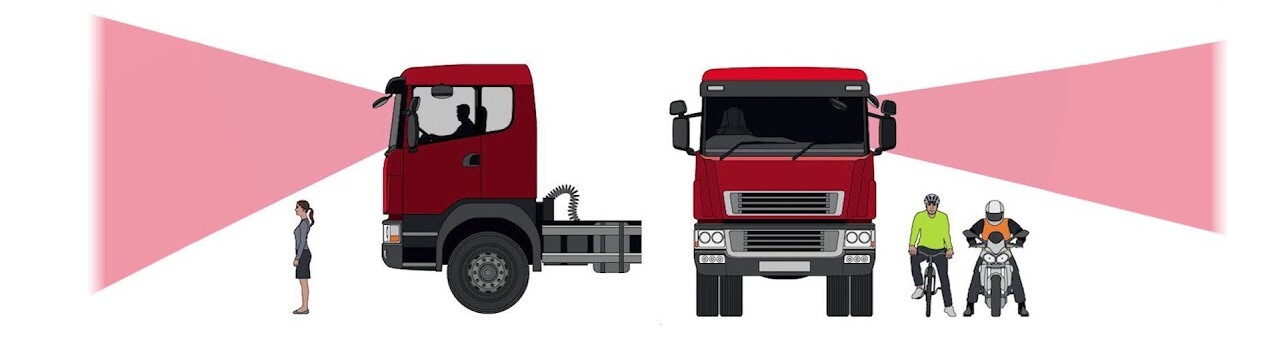

Every year more than 500 cyclists and pedestrians are killed in truck collisions across Europe. Typically, the truck driver simply doesn’t see the cyclist or pedestrian. The most common crashes are all too familiar. A cyclist crushed, unseen by the driver of a turning truck; a pedestrian directly in front of the cab, below the driver’s line of vision, unseen as the truck moves off.

For every recorded death, another five cyclists or pedestrians suffer serious, life-changing, injuries. The story of trucks’ disproportionate impact is summed up by a very simple statistic: trucks make up 2% of vehicles on European roads but are involved in 14% of fatal collisions. In a crash, the sheer bulk of a truck tends to give little chance to the human body.

The fix has long been clear: bigger and better positioned windows, with the driver’s cab lowered down to a height similar to large vans. Known as “enhanced direct vision”, these design changes allow drivers to see far more of the space around the cab, thereby getting rid of blind zones.

The new law sets deadlines to enlarge the areas that the driver can see from the cabin of new trucks. By January 2026, new designs (so-called ‘newly type approved vehicles’) must meet the standard across the EU and UK. Three years later, every newly-sold truck must comply, irrespective of the date when it was type approved. The new standards also apply to buses and coaches, but their direct vision is already generally far better than most trucks.

The new standards, however, don’t go far enough. According to vehicle safety specialist, Steve Summerskill of Loughborough University School of Design and the Creative Arts, “the new standards should help reduce collisions where cyclists are crushed by turning trucks. But it’s a different story where pedestrians are knocked down by trucks moving off from rest. Here, there’s a risk that the current version of the standard could allow truckmakers to improve performance to the front in low risk areas only. An amendment is needed to ensure truckmakers do not take this approach.”

The gains from clean sheet design

Over the next five and a half years, truckmakers falling short of the standards will either have to bring better cabs to market, or exit segments where they no longer comply. But the transition to electric trucks – a shift most truckmakers are already making – offers great scope to enlarge the areas that the driver can see from the cabin. Volta Trucks, an e-truck start-up focused on the urban delivery segment, shows what’s possible. Its new e-truck, the Volta Zero, is understood to deliver more than 30 cubic metres of direct vision, according to a soon-to-be-published study by Loughborough University. This level of direct vision is around three times the minimum requirement for urban trucks under the new standards. According to the company, drivers of the Volta Zero “sit in a low and central position, eliminating blind spots, and mirroring the eye-line of nearby pedestrians and other road users for easy visual communication”.

E-truck development unconstrained by existing production is commonly known as ‘clean sheet design’. It involves two main changes, both enabling direct vision to be enhanced while cleaning up the powertrain.

- The first change, referred to by Volta Trucks, is dropping the cab down to a level similar to a large van. Electric trucks require relatively few components to be located directly under the driver. Instead, most of the powertrain – particularly the battery – can be embedded along the floor of the truck, particularly between the axles. Another new entrant, Tesla, appears to have adopted a similar design strategy, with online images showing all of its batteries placed between the front and rear axles.

- The second aspect is the central driving position favoured in clean-sheet electric trucks. Moving the driver’s seat to the middle of the cab helps to increase the driver’s direct vision, but is really only possible when designers are freed from existing production line configurations used to build trucks with the driver on one side or the other.

The promise of clean sheet e-truck design is a huge boost for greater direct vision. Steadily, truck design can migrate from the old world of cab-over-engine and drivers way up high, to a new world of batteries-between-axles and drivers close to the eye level of pedestrians and cyclists. Visualising that change, it’s a shift away from the truck shown in red below, to the cab design shown in blue.

Vulnerable road users are not directly visible by the driver of traditional cab-over-engine trucks. Image: Transport for London

Cab design that enables vulnerable road users to be seen by drivers. Image: Transport for London

How to get to zero blindspots

The phasing out the sale of worst-vision trucks is a success of sorts in the new standards, but as an initial step rather than a destination. At EU level, the European Commission is required to review vehicle safety legislation by July 2027. The clear route to getting rid of blindspots is to increase the performance levels (see table below), and add safeguards to ensure the vision improvements focus on the areas of highest risk.

Vision Zero, the EU’s goal to reduce road deaths to zero by 2050, logically demands getting as close as possible to the complete elimination of blindspots in new trucks. As fossil fuel engines are phased out of new production in favour of electric powertrains, there’s scope to secure far safer trucks. E-trucking can finish the job on blindspots.

As campaigning for the 2024 elections gathers momentum, it will be important to inform candidate MEPs of the synergies between climate and safety goals – and, more importantly, their agency to convert this potential into cleaner and safer streets.

UNECE direct vision standards: minimum visible volume by vehicle category

| Level | Working description | Field of vision (cubic metre minima) |

| 1 | Urban delivery trucks; buses & coaches | 11.2 |

| 2 | Construction trucks most used in cities | 8 |

| 3 | Long haul highway / motorway trucks | 7 |

Postscript: a brief words of thanks

The method of measuring a truck’s field of vision was developed by Transport for London in collaboration with Loughborough University School of Design and the Creative Arts (SDCA). Safety advocates owe a debt to the work of Dr Steve Summerskill and his colleagues at SDCA. Thanks also to T&E’s lead funder on truck safety, the FIA Foundation, for its truly long-term commitment since 2014 to addressing this deep-seated problem. Kudos too to the vital work by the European Commission, Transport for London, vehicle safety specialists, key national officials, and a number of highly-dedicated truck designers.